PROCESSING SERVICES

Our experts will process your material efficiently and cost effectively.

Slitting

Slitting

Blanking

Blanking

Cut-to-Length

Cut-to-Length

Toll Processing

Toll Processing

Finishing Services

Prepainting

Cleaning, priming, and painting extra smooth steel to precise specifications. We can fulfill virtually any specified color to meet and exceed even the most exacting surface and color needs of our customers.

Perforating

The process of punching small holes in a specific diameter and pattern. Perforating is often seen on products like speakers and intercom facings. We can service the specialized perforation needs of each customer.

Embossing

Coated or uncoated steel with a specified pattern rolled into the surface. Embossing is typically utilized on food cases, restaurant equipment, and other exteriors for its aesthetic value.

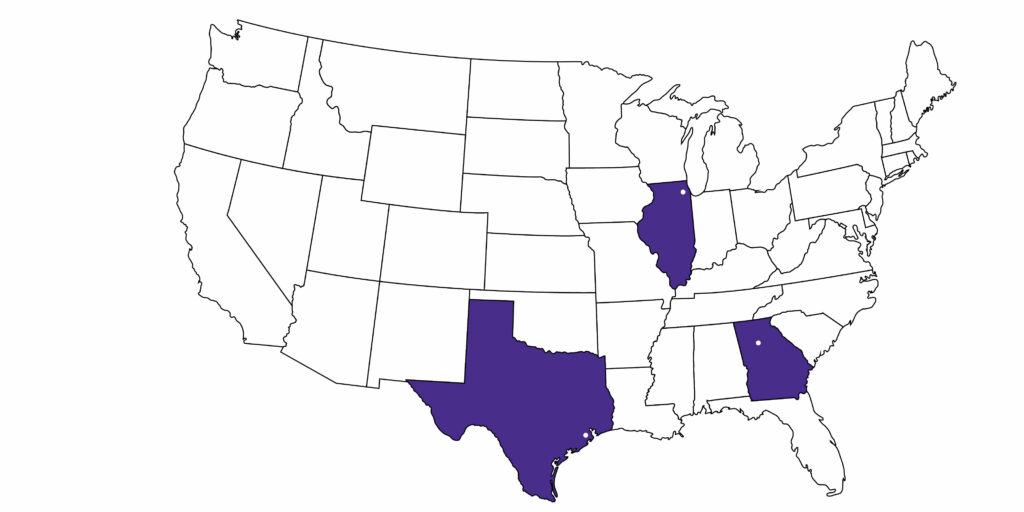

Global Reach, Local Execution

We deliver value through efficiency.

Mills, end users, and other steel distributors have leveraged our processing efficiencies to add value and lower costs in their supply chain.

Houston, TX

Pacesetter Service Center

Atlanta, GA

Pacesetter Service Center

Chicago, IL

Pacesetter Service Center

Pacesetter can also create customized supply chains utilizing our vetted network of toll process partners to enhance capabilities and minimize logistics.