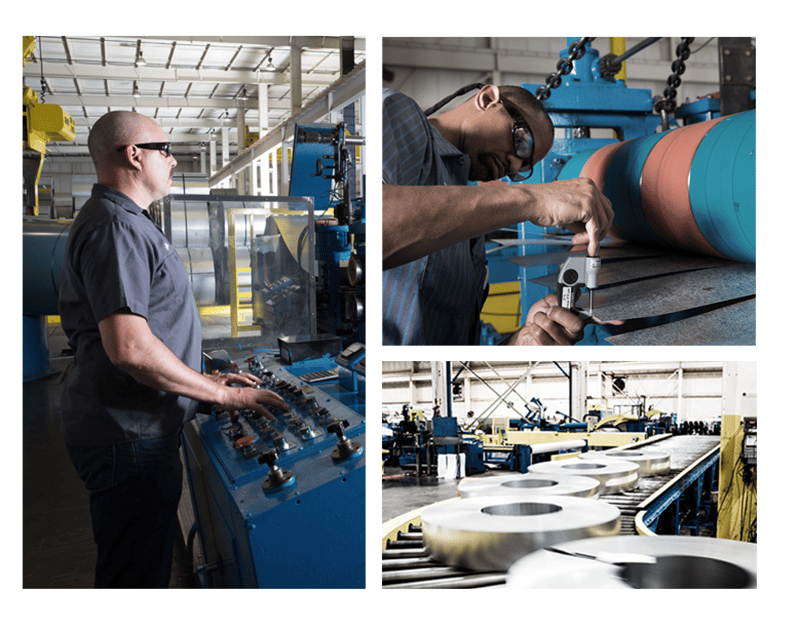

High-quality steel products and finishing services to meet your standards.

We begin with prime, flat-rolled steel, such as galvanized, cold rolled, galvannealed, aluminized, stainless, and bonderized steel, and process it to meet our customer’s specific requirements.

Type 1 aluminized has a coating of approximately 85% aluminum and 15% silicon

Type 2 aluminized has a coating of commercially pure aluminum

Stainless steels are iron alloys with a minimum of 10.5% chromium

Alloying elements enhance formability, strength and cryogenic toughness

Steel substrate and a 99% zinc coating

Need it UL Certified? We do that too

Steel substrate with a zinc-iron alloy coating

Zinc phosphate treated galvanized steel

Inhibits corrosion and promotes paint adherence

Finishing

While no two projects are exactly alike, our dedicated team of experts have seen it all. They can guide you through a typical order or a highly complicated set of specs to give your team peace of mind.

Prepainting

Cleaning, priming, and painting extra smooth steel to precise specifications. We can fulfill virtually any specified color to meet and exceed even the most exacting surface and color needs of our customers.

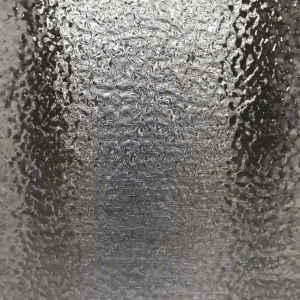

Embossing

Coated or uncoated steel with a specified pattern rolled into the surface. Embossing is typically utilized on food cases, restaurant equipment, and other exteriors for its aesthetic value. We help each and every customer get the look and specifications they want.

Perforating

The process of punching small holes in a specific diameter and pattern. Perforating is often seen on products like speakers and intercom facings. We can service the specialized perforation needs of each customer.